Project Description

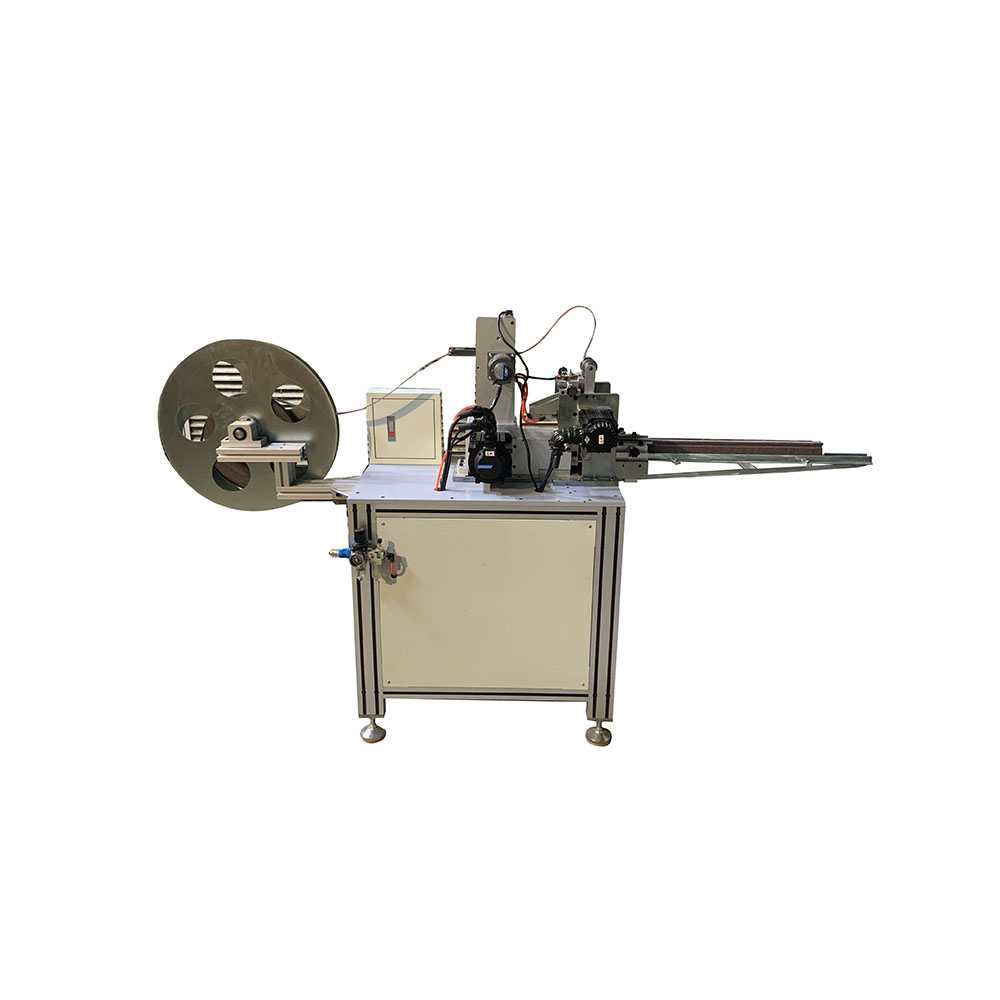

ABR-FCF-1600 is designed mainly for abrasive flaps punch cutting directly from abrasive jumbo roll.

It can punch 1600mm width one time, with high cutting performance.

On this machine, stripe & U shape flaps are both available by using different kinds of cutting die.

Equipped With

Equipped with 80T punch pressure, higher performance

Equipped with automatic raw material continuous feeding & flaps delivery system

High cutting performance with low noise, and low power consumption

Equipped with PLC control system, easy operation

Equipped with counting system, make machine stop working after produce certain quantity.

Double oil cylinder, precision four-column automatic balance link structure, keep every piece of flaps be cut off in same force.

Central automatic lubrication system, keep machine in high precise working and maintain in good condition.

Easy adjust punch depth and punch lift distance on machine

Long working life

Technical data

Cutting force: 80Ton

Cutting speed: 35~40 times punch per minute

Suitable flaps size: any size, depend on cutting mould

Suitable material width: 1600mm

Suitable material: various kind of abrasive cloth/ paper

Working stable area: 1600*610mm (other size can be customized.)

Punch head lift & down stroke: 55~165mm

Power: 7.5KW

Voltage: 3 phase 380V