Project Description

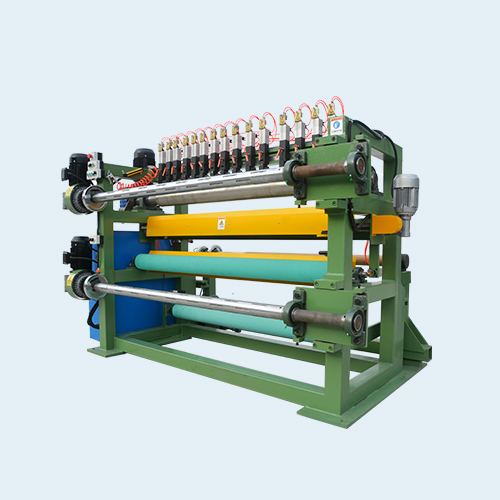

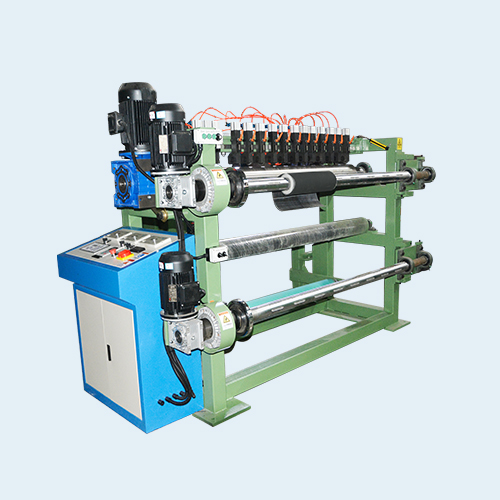

Premium Flap Disc Full Auto Manufacturing Machine

The flap disc machine ABR-FAFD-180 is a new model of full automatic machine for flap disc production, with lots of update compared with ABR-FAFD-180. From raw material feeding, loading on station, to finished flap disc unload on metal rod. Worker only need to put backing pad on metal rod, and put abrasive ribbon rolls on material shaft. High automatic, save labor.

Technical Info

Product diameter size range: 75~180mm

Production shape: T27 & T29

Production model: single flap flap disc/ double flaps flap disc/ non-woven flap disc/ M14 flap disk

Suitable backing pad material: fiberglass/ metal/ plastic

Production speed: 800~1000 pcs/hour

With glue pump, can choose 30KG type or 300KG type

Glue coat quantity: 3~30g, with precise adjust system

Equipped with ratio valve and air container to make sure the glue coating is always uniform

Adopted with profession heating system for glue heating, temperature error is within ±2℃

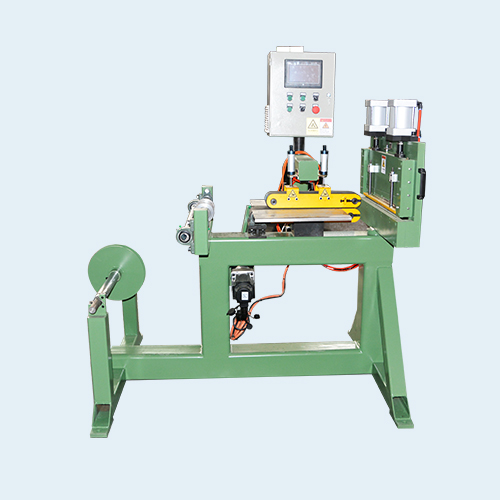

Flap cutting head can be flexible adjusted in 6 directions & in tilting angle

With protection cover outside

Flap width range: 11~35mm

Flap length range: 14~22mm

Cutting head up & down movement can be automatically adjusted.

Cutting head is very easy to be adjusted, save time when you need to shift from different size production.

Inovance PLC control system & electric parts, and bus control, which would ensure a very stable system

Precise transmission system

Automatic backing pad loading system

Automatic finished product unloading system

With a flap disc bunch press unit

Servo motor control transmission

Equipped with vacuum dust collector

Basic Parameters

Power: 9KW

Electric supply: 380V, 3 phase/ 50HZ

Pneumatic supply: 0.7Mpa

Main part dimension: 2600* 1600* 1500mm

Glue pump dimension: 1100* 650* 1800mm

Weight: 1000KG